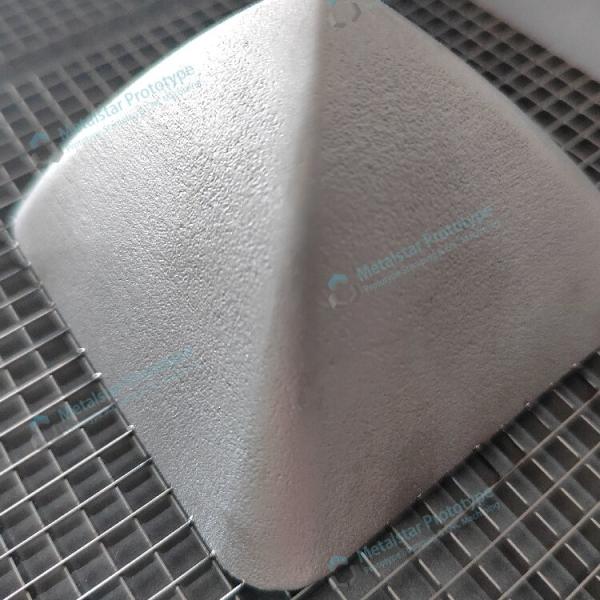

Metalstar specializes in providing quick quality sheet metal

stamping prototypes, CNC aluminum machining and CNC steel

machining parts. With our industrial experience accumulation

for more than 20 years, we have the capacity to supply 1 to 5000+

high quality sheet metal stamping parts, CNC machining parts

or other customized parts for you from 5 to 30 days at

competitive price.

WHO WE ARE

Metalstar Prototype was established in 2003 in Guangzhou city of

China. We specializes in providing prototyping stamping, CNC

machining (covers CNC aluminum, CNC steel and CNC plastic parts),

hardware customization service and provide relevant surface

finishing options in variety. With our industrial experience for

more than 20 years, we have the capacity to supply 1 to 5000+ high

quality prototype stamping parts, CNC machining parts or custom

hardware for you from 5 to 30 days at competitive price.

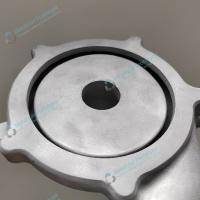

Our factory locates in the most famous area of China for supplying

high quality prototype stamping parts, CNC machining parts and

custom hardware. Our 58000-square foot workshop equips the

equipment and devices to turn your innovative ideas into practical

solutions. For more than 20 years, Metalstar prototype team has

earned a reputation for providing quick quality custom parts to

industries throughout Guangdong province, the whole China, and

internationally.

OUR MISSION & GOAL

Our mission is to build a factory that all Metalstar people can be

proud of. To employ the best talents, acquire the most advanced

technologies, and use the world’s most efficient manufacturing

techniques to bring to our customers a unique and refreshing

cooperation experience.

Our goal is always being a trusted partner, to establish long-term

partnership with our customers. Whether you require a

prototype, a small batch of custom parts or a large-scale

production run, you can count on Metalstar prototype to be your

reliable, responsive, and innovative partner.

OUR VALUES & CHANT

We wrote this chant to help remind all our employees that the

key principles of manufacturing that he considers core to an

efficient and well run factory.

1. How do we become more efficient and satisfy our customers?

2. Plan, Plan, Plan; Team, Team, Team.

3. Think lean, act large and strive to be better.

4. Practise promise, do what we said we would do.

5. Get it right, first time, every time.